| Shipping Type | Order By |

|---|---|

|

Standard Ground Small Parcel FREE - On orders over $25 View Transit Map |

7:00 PM CST |

|

Next Day Air (Calculated at checkout) |

3:00 PM CST |

|

Standard Ground Freight FREE - On orders over $25 |

1:00 PM CST |

- Shipping cutoff times apply to in-stock items. Please note item lead-times when placing your order.

- Orders placed on weekends or holidays will be processed the next business day.

Wall Mounted Fans

Performance Filter

Shop Greenheck Wall Mounted Fans

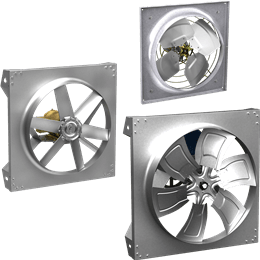

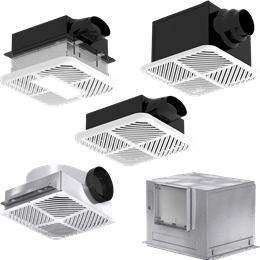

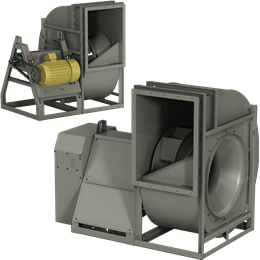

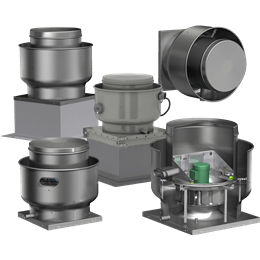

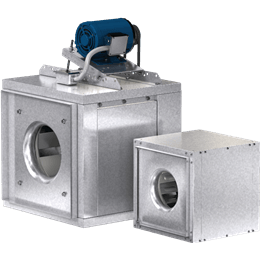

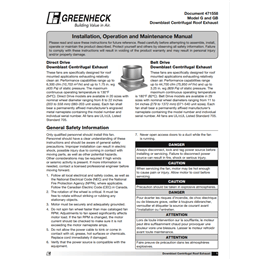

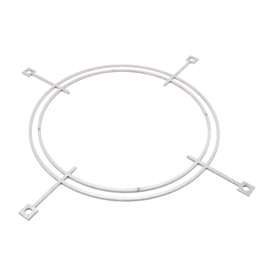

One of the most crucial components to any HVAC project are your wall mounted fans. Mounting ventilation fans on walls is a great way to save space for the more important work taking place within your warehouse, commercial kitchen, manufacturing facility or any building. The Greenheck line of wall mounted fans are the industry standard in clean air exhaust and air movement. We manufacture wall fans which are available in belt or direct drive, axial or centrifugal configurations.

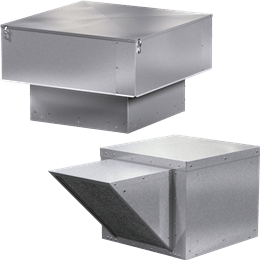

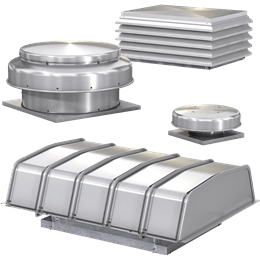

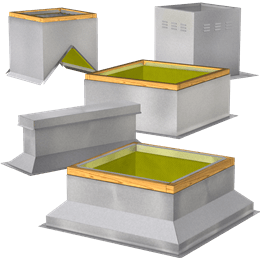

Our centrifugal line of wall mounted fans are ideal for contaminated air exhaust where grease laden materials are handled. Available in both belt and direct drive, the CUBE and CUE fans can mount flush to the wall with our wall mount bracket or offset using a traditional curb mounting. For clean air exhaust, look no further than model SBE and SE1 axial fans. By using our online store for your order, you can package all the necessary mounting accessories and control options. We are also proud to offer custom building services to meet the needs of any HVAC challenge. All this on top of our outstanding Warranty, Educational Resources, and world class customer support at exactly why Greenheck wall mounted fans are the best choice in the industry.